7

Industry : Pharmaceutical

Place :

France

Objective : Flash steam

recovering from a

feed tank

Solution : Install a heat

exchange solution

EVC

Result :

Energy recovered is

63 000 €/per year

Payback period : 12 months

Case Study

The problem :

Our customer had a 6 bars steam system on his site, aimed to feed

various production processes. The water return process is made

through a condensate system. These condensates are stocked

in a tank and have a temperature about 98°C to 100°C. 7% of

the condensate return throughput is evaporated and released in

the atmosphere via an insulated stainless steal 300mm diameter

duct located on the tank. The customer desired to use this energy

instead of losing it.

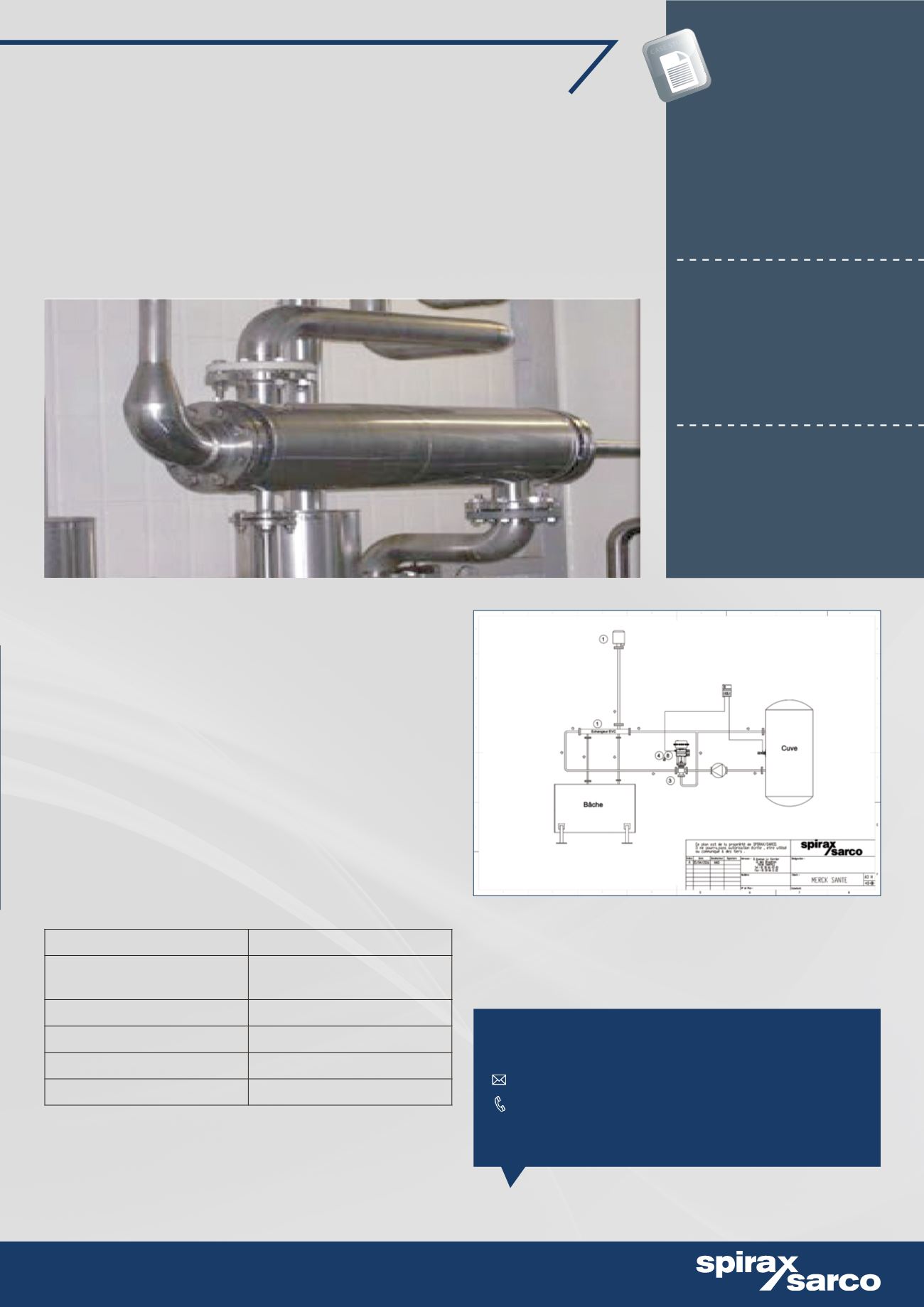

Spirax Sarco Solution :

To create a heat exchange solution to heat the secondary fluid

thanks to the energy recovered from flash steam. The EVC solution

allows to heat and maintain the water temperature around 78°C

which is currently heated electrically.

Results :

Energy recovered (steam)

300 kg/h

Secondary fluid heated and

maintained at

78°C

Condensate throughput

8 000 kg/h

Energy recovered

187,5 kW

Energy recovered value

63 000 € per year

Payback period

Less than 12 months

The Spirax Sarco EVC solution uses a feed tank flash

steam to heat a secondary fluid and allows a customer

to recover 63 000€ of energy per year

CASESTUDY

For more informations about EVC or one of our products or services,

please contact :

export.uk@uk.spiraxsarco.com +44 1242 573703